Cylindrical Coils: Low-Voltage vs. High-Voltage

Cylindrical coils are categorized into low-voltage and high-voltage types. Low-voltage cylindrical coils are typically used in three-phase transformers with capacities ≤630 kVA and voltages ≤1 kV. High-voltage cylindrical coils, however, are applied in three-phase transformers with capacities ≤630 kVA and voltage ratings of 3–35 kV.

Low-Voltage Coils

Low-voltage coils are wound using one or multiple flat conductors in parallel. Increasing the number of parallel conductors reduces the number of turns per layer, worsening the coil’s fill factor. For transformers above 630 kVA, foil coils are preferred to improve fill factor.

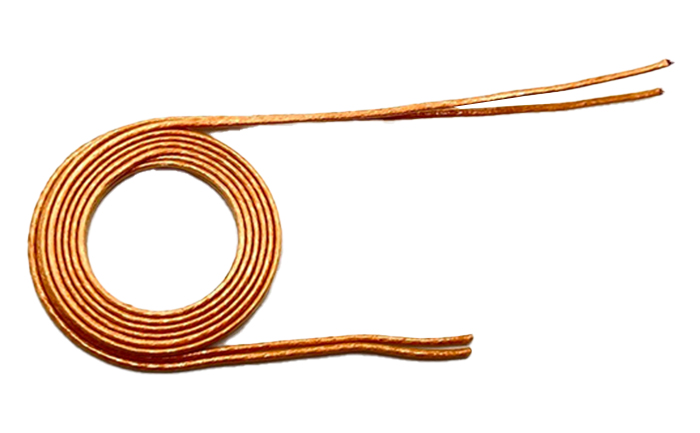

High-Voltage Coils

High-voltage coils use round conductors. When segmented cylindrical coils are employed, they can be used in transformers up to 2000 kVA and 63 kV. Cylindrical coils feature simple winding processes and excellent heat dissipation through interlayer oil ducts but lack mechanical strength, so single-layer designs are generally avoided.

Spiral Coils

Spiral coils are used in low-voltage, high-current transformers with capacities ≤800 kVA and voltages ≤35 kV. These coils are wound by twisting multiple flat conductors into a spiral. Variants include single, double, and quadruple spirals. Parallel conductors at different radial positions require transposition during winding to compensate for length differences.

Continuous Coils

Continuous coils, widely adopted for their mechanical robustness and thermal performance, are used in transformers with capacities ≥800 kVA and voltages up to 110 kV. They consist of multiple pancake-shaped segments (30–100) wound continuously on a mandrel. Segment counts are even (for end connections) or multiples of 4 (for mid-coil connections). Parallel conductors (≤4 in general, ≤8 in special cases) are transposed between segments to minimize circulating currents.