Wireless charging transmitter coils are core components of wireless charging systems, responsible for efficiently transmitting electrical energy to receiver devices via electromagnetic fields. Below is a detailed explanation from technical principles, structural characteristics, material selection, design challenges, and typical applications:

1. Working Principles

Based on electromagnetic induction (Qi standard) or magnetic resonance:

Electromagnetic Induction: The transmitter coil generates an alternating magnetic field when AC power is applied. The receiver coil induces current through Faraday's Law, which is rectified to charge the device.

Magnetic Resonance: Transmitter and receiver coils resonate at the same frequency, enabling mid-range energy transfer (common in electric vehicle charging).

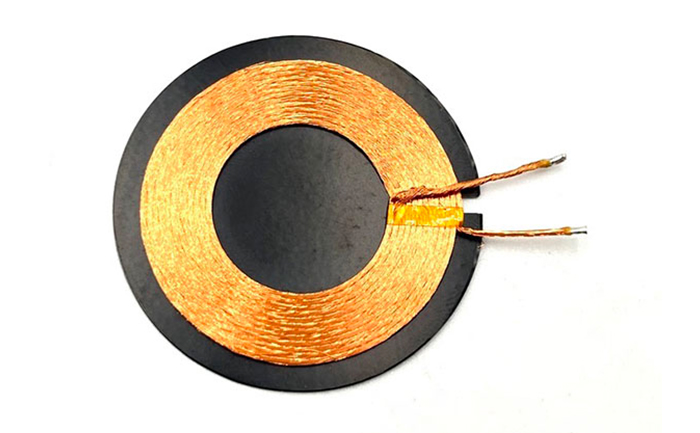

2. Structural and Design Features

Shapes:

Planar circular/rectangular: Used in smartphones, earphones.

3D spiral: Enhances magnetic coverage for EVs or high-power applications.

Parameter Optimization:

Turns: Higher turns increase magnetic strength but raise internal resistance.

Wire diameter: Thicker wires reduce resistance (heat) but limit high-frequency performance.

Size: Matched with receiver coils for efficient coupling.

Materials:

Conductors: Litz wire (multi-strand copper) minimizes skin effect; silver-plated copper improves conductivity.

Magnetic cores: Ferrite sheets enhance field concentration.

Shielding: Aluminum/copper layers comply with EMC standards.

3. Circuit Integration

Driver Circuit:

Power amplifiers convert DC to high-frequency AC (100–205 kHz).

Resonant capacitors form LC circuits for efficiency.

Control Unit:

Communication modules negotiate power levels (e.g., Qi protocol handshake).

Protection circuits prevent overvoltage, overcurrent, and foreign object detection (FOD).

4. Design Challenges

Efficiency:

Coil alignment: Magnetic shaping (e.g., ferrite sheets) reduces misalignment losses.

Dynamic tuning: Adjust frequency in real-time for load changes.

Thermal Management: Heat dissipation via heatsinks or liquid cooling.

Cost Control: PCB coils replace hand-wound alternatives.

5. Applications

Consumer electronics: Phone chargers, smartwatches.

Automotive: EV charging pads (7–11 kW).

Industrial/medical: Robot charging, implantable devices.

6. Future Trends

Multi-device charging via coil arrays.

Long-range transmission using resonant coupling and beamforming.

Integration into furniture/smart surfaces.

Wireless charging transmitter coils require expertise in electromagnetics, materials science, and thermal management. Advances in these fields will drive seamless integration into daily life and industry.